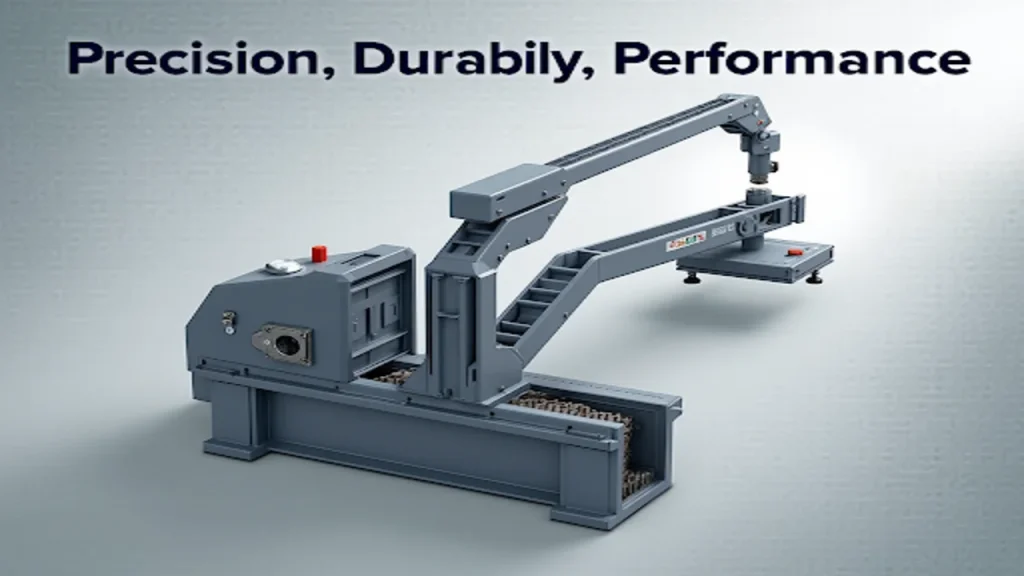

The Butler G4B25 has emerged as a game-changer in the world of industrial mechanics, offering unparalleled versatility, precision, and durability. This swing arm mechanism, renowned for its heavy-duty construction and adaptable design, is a staple in industries ranging from automotive to robotics. With its ability to support heavy loads and deliver seamless movement, the Butler G4B25 ensures efficiency and reliability across diverse applications.

What is the Butler G4B25?

The Butler G4B25 swing arm is an industrial-grade component designed to facilitate controlled, articulated movements in machinery. Built with precision engineering, it is crafted from high-grade steel and incorporates advanced bearings for smooth operation. Its corrosion-resistant coating and customizable attachments make it suitable for a wide range of environments and applications.

Whether it’s enhancing operations in an auto repair shop or streamlining production in factories, the Butler G4B25 has proven to be a versatile tool for tackling complex mechanical tasks.

Key Features of Butler G4B25

Heavy-Duty Construction for Rigorous Tasks

The Butler G4B25 is constructed from high-grade steel, making it resilient to heavy loads and harsh operating conditions. Its robust design ensures durability even in high-pressure environments like industrial machinery and construction sites.

Precision Engineering for Seamless Movement

Equipped with advanced bearings, the G4B25 delivers effortless and accurate movement, reducing wear and tear over time. This precision is essential for tasks requiring high levels of accuracy, such as robotic system integration.

Adjustable Swing Radius for Versatility

One of the standout features of the Butler G4B25 is its adjustable swing radius, which allows users to customize the arm’s range of motion. This adaptability ensures optimal performance in both confined spaces and large-scale operations.

Customizable Attachments for Tailored Operations

The swing arm can be fitted with various tools, making it highly customizable. From handling lightweight components to managing heavy-duty applications, its modularity caters to specific operational needs.

Corrosion Resistance for Longevity

The addition of a specialized corrosion-resistant coating enhances the arm’s lifespan, making it ideal for use in challenging environments, such as construction sites or areas with high humidity.

Applications of the Butler G4B25

Automotive Industry

In repair shops, the Butler G4B25 aids in vehicle lifting and tire-changing operations. Its load capacity and precision make it indispensable for mechanics seeking reliable performance.

Industrial Machinery

The swing arm enhances production efficiency by facilitating the movement of components on assembly lines. Its durability and precision engineering reduce downtime, ensuring smooth operations.

Construction Equipment

Built to withstand rigorous tasks, the G4B25 is a reliable choice for heavy-duty machinery used in construction. Its strength and adaptability make it a preferred component for handling complex loads.

Robotic Systems

The precision and flexibility of the Butler G4B25 enable seamless integration into robotic arms, where it contributes to complex movements and tasks in automated systems.

Repair Shop Utility

With its ability to support various attachments, the swing arm excels in repair shops, where it streamlines operations like part handling and equipment adjustments.

Installation and Maintenance Guide

Step-by-Step Installation Process

- Choose a Stable Surface: Ensure the base is capable of supporting both the arm and the loads it will handle.

- Secure Fasteners: Use high-grade bolts to anchor the swing arm firmly.

- Check Alignment: Ensure the arm is aligned for smooth, unrestricted movement.

- Attach Custom Tools: Fit attachments as per operational needs.

Regular Maintenance Tips

- Lubrication: Periodically lubricate moving parts to minimize friction and wear.

- Inspection: Regularly check for signs of damage or misalignment.

- Cleaning: Remove debris to prevent operational hindrances.

- Fastener Tightness: Ensure all bolts remain secure to maintain stability.

Performance Benefits of Butler G4B25

Improved Operational Efficiency

The G4B25 enhances productivity by ensuring precise and controlled movements, reducing operational time.

Enhanced Safety Standards

With its robust construction and reliable performance, the swing arm minimizes the risk of mechanical failures, ensuring safer working conditions.

Long Lifespan

Its high-quality materials and corrosion-resistant coating guarantee a long service life, even in demanding environments.

Versatility Across Industries

From automotive applications to industrial production lines, the G4B25’s adaptability makes it a valuable asset across various sectors.

Cost-Effective Solution

By reducing wear and requiring minimal maintenance, the Butler G4B25 proves to be a cost-effective choice for businesses.

Comparison with Competitors

| Feature | Butler G4B25 | Competitor A | Competitor B |

| Material Quality | High-grade steel | Mid-grade aluminum | High-grade steel |

| Corrosion Resistance | Yes | No | Yes |

| Adjustable Swing Radius | Yes | Limited | Yes |

| Load Capacity | High | Medium | High |

| Customizable Attachments | Yes | Limited | Yes |

| Maintenance Requirements | Low | Moderate | High |

The Butler G4B25 clearly stands out for its combination of durability, precision, and versatility, outperforming competitors in critical areas such as load capacity and maintenance efficiency.

FAQs About the Butler G4B25

1. What is the load capacity of the Butler G4B25?

The swing arm is designed to handle substantial loads, making it ideal for heavy-duty applications.

2. Can the Butler G4B25 be customized?

Yes, it supports various attachments that cater to specific operational needs.

3. How does the adjustable swing radius work?

The feature allows users to modify the arm’s range of motion, enhancing its versatility.

4. Is the Butler G4B25 suitable for robotics?

Absolutely! Its precision and flexibility make it a popular choice for integration into robotic systems.

5. What industries commonly use the Butler G4B25?

It is widely used in automotive, construction, and industrial machinery sectors, among others.

The Butler G4B25 is a testament to advanced engineering and industrial innovation. With its exceptional features, versatile applications, and proven reliability, it continues to set benchmarks in mechanical efficiency. By understanding its benefits and maintenance requirements, businesses can maximize its potential and ensure lasting performance.

Stay tuned for more insights on the Butler G4B25 as we dive deeper into its impact across industries!

Also Read: Important Factors to Consider Before Choosing Interior Carpentry Service?